Why Virtual Reality Offers Viable Solutions To Serious Problems

For many of us, there’s still a common misconception that Virtual Reality (VR) is a gimmicky gaming gadget used for fun and product promotion. That may have been the case in the mid-1990s when the technology first found commercial success, but today it’s a very different story.

Although some people think of VR in terms of the hardware, such as headsets and gloves, it’s actually the software inside it – which creates virtual representations of the real world – that offers the most business value. When you stop to think about it, the scope of using VR to solve real-world challenges is huge. In fact, these days, VR is an enabling technology for all kinds of engineering applications.

More Than A Toy

Over the past decades, VR has evolved alongside computer technology. Gone are the days of blocky Minecraft-like representations of the human world. Today’s VR is capable of replicating the appearance and functionality of sophisticated machines, from robotic equipment to cranes and ships.

Not only that, in a world of increased automation and ‘Big Data’ VR simulation is able to offer cost-effective solutions for testing new and expensive machinery – even before it’s gone into production. More incredibly, VR simulation can take place within the context of a real-world environment, whether that’s deep under the ocean or in weather conditions modelled on real data.

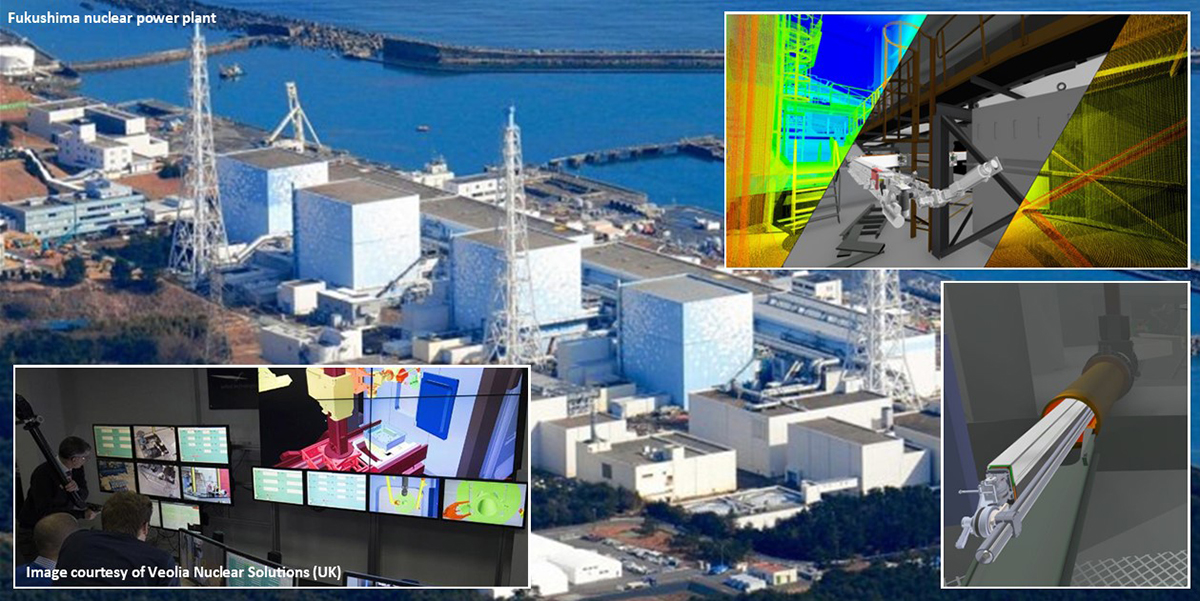

With modern hardware and the detailed data, it’s possible to compute and simulate highly realistic machine behaviour, draw conclusions, and apply them to the real world. That could be anything from nuclear decommissioning to subsea monitoring.

Test Scenarios

VR simulation can be a powerful tool for testing equipment in the engineering phase, and for predicting its behaviour in real-world conditions. In addition, when machinery is up and running, it can be used to test out scenarios virtually before they take place in reality. For that reason, the accuracy and reliability of simulation is critical.

Using accurate data like physical properties of equipment and environment, combined with real-world sensor measurements, a simulation can be trusted to be a very close approximation of what will actually happen in the real world. Through high end physics simulation, interactions between equipment and environment are modelled realistically. Collisions can be detected and even forces on equipment parts can be plotted during simulation.Thinking of it in those terms, VR simulation becomes a viable and trustworthy solution to some of the world’s most serious challenges – such as operating heavy machinery in dangerous conditions.

For example, in nuclear decommissioning, radiation levels can be high. This means that operations need to be executed by remotely operated technology. However, high radiation can interfere with cameras. That’s where VR comes in. Not only can it be used to prepare for these missions, it can also provide an accurate visualisation of the live operation when connected to the actual control systems.

Putting Safety First

Another example of the industrial application of VR is in subsea monitoring. It goes without saying that for humans, subsea conditions can be potentially life-threatening. That’s why remote controlled equipment is used to keep human operators safe. Remotely Operated Vehicles (ROVs) are often used for subsea maintenance and inspection.

Remotely operated technology is also deployed in subsea cutting or dredging equipment to support wind farms or the hunt for rare earth materials. When the seabed is manipulated, this causes turbidity and cameras go to black. An accurate digital representation can provide operators with the necessary visual feedback to continue their operations efficiently and safely, preventing damage to expensive equipment.

By continually feeding a simulation with increasing amounts of real-world data, VR can be used to more accurately predict the outcomes of different circumstances and help to mitigate future real-life disasters. Essentially, it can be used to recreate the real world as accurately as possible in order to understand and manage potential risks.

De-risking And More

It’s clear that whilst de-risking might be the overall goal, the industrial applications of VR come with other inherent advantages: improved safety, and cost-effectiveness.

Operations are complex and equipment is expensive. Any damage can cause costly delays and also repairs are expensive. A simulator can prevent this by providing high fidelity operator training and clear visualisation of the live operation.

Typically, methods and equipment are newly-designed for a specific task. This means a reliable test environment is vital to ensure the engineered equipment is fit for purpose. VR technology enables the accurate virtual testing of fully-functioning equipment – before, during, and after production.

At Tree C we develop realistic digital twins of both equipment, and environments. Learn more about what we do.