Tree C: What We Do & Why We Do It

Tree C is a private simulation software company based in the Netherlands. Back in 1994, we were a software reseller in the field of computer assisted manufacturing. Today, Tree C’s powerful simulator framework provides flexible generic digital twin technology across a range of sectors in the offshore and remote handling industries.

Our early customers were people like architects who needed to turn 2D plans into 3D visualisations. More recently, our software is commonly used for engineering projects in inaccessible environments. In fact, wherever there’s a need to plan and test highly-complex and costly engineering solutions, as well as provide operational monitoring and training – our software can help drive down costs, and create operational efficiencies.

In this blog post, we share the Tree C story, what we do, why we do it, and how our 3D simulations and Digital Twin technology can add value to complex engineering projects.

From 3D Visualisations To Digital Twins

After being involved with a number of 3D visualisation projects, the opportunity arose to take the original business and turn it into a company in its own right. After creating what would become our flagship VR4MAX product for a single project, our offering quickly evolved into a full software solution with multiple applications across a range of industries.

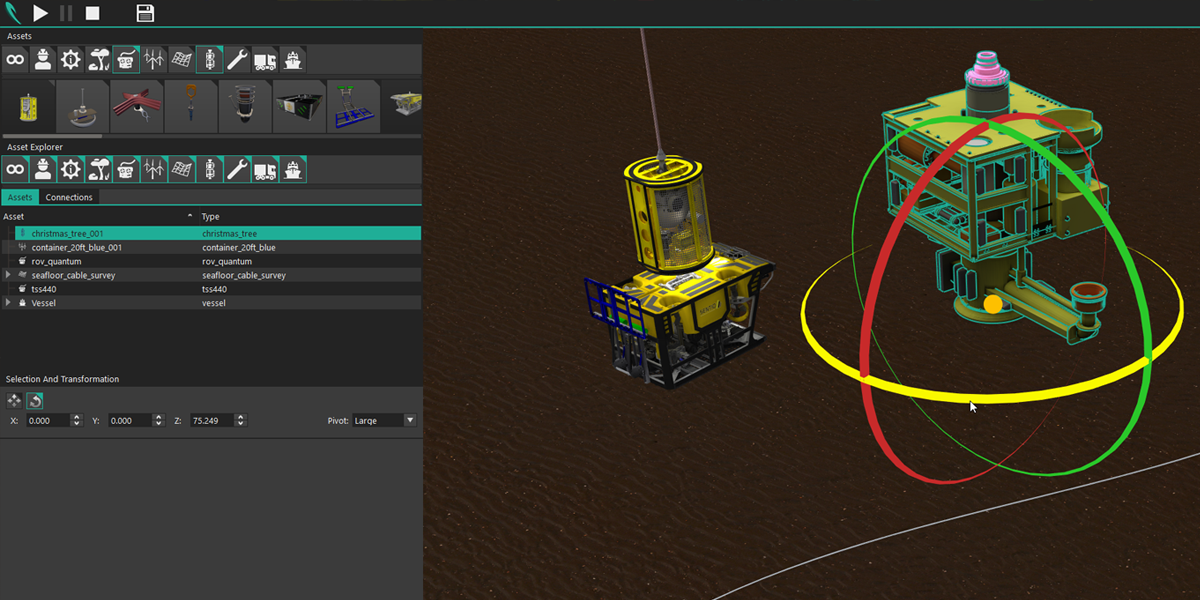

The versatility of our software means it can be used in almost any industry to plan and test operations. As a business, a significant turning point came when Tree C moved toward more offshore-related projects, such as deep-sea mining and remote-handling activities, including nuclear decommissioning, where VR4Robots answers the complex demands from this industry.

We know that different industries have similar challenges, and so our purpose has naturally evolved into the application of 3D simulation and digital twin solutions to de-risk highly-complex industrial engineering projects. We do this by creating training simulators that help operators work safely and efficiently, and minimise the chance of making mistakes.

At the same time, our technology is used by engineers to test their designs in a digital environment before launching into production. This keeps costs down and processes streamlined.

Another powerful application of the technology is providing real time visualisations of ongoing operations, a clear visual when operating in low visibility conditions can make the difference for operational efficiency and safety.

Real-World Systems In A Virtual Model

It’s by creating fully interactive virtual representations of physical, real-world environments and systems that we can add the most value for our clients. There are two ways we do this.

Firstly, our clients can send us their 3D CAD models, which we then convert and upload into a 3D modelling application, preparing the content to make it ready for interactive simulation. We add physics and behaviours to the models, before exporting them to our product in a virtual environment, so it behaves like real equipment.

Secondly, our software has a CAD importer which provides direct entry into the VR. This makes the workflow for content creation and model updates highly efficient.

When developing a simulator, getting the 3D models into the system is just one aspect of the development. Hardware is also in the loop, so we have to connect with hardware control systems and devices, and investigate what kind of signals need to be exchanged to mimic the actual equipment. Signal processing is therefore a key consideration, as is additional intelligence, and warnings, which all have to be added to the algorithm.

It goes without saying that the complexity of a project determines the set-up. However, regardless of the size and scope of the simulation, everything inside it has to comply with the rules of natural physics.

Engineering, Testing, Training and Monitoring

Our aim is to support heavy equipment, offshore and remote handling operations with advanced 3D simulation technology.

With advanced physics simulations, we’re able to visualise real environments and physical equipment to support engineering, enable the safe testing of equipment and controls, train operators to prepare for their missions or provide live operational monitoring

We have three main approaches to helping our clients:

- Software Licence: We deliver our software to a client, and they manage the entire process and project. They buy a licence with a support package to help them get started.

- Co-operation Mode: An ongoing collaboration where we handle simulator development alongside a client who is trained and supported to eventually take over independent ownership.

- Turnkey Simulator: This starts with a specification phase where we determine the required level of complexity, and specific training needs, ultimately delivering a complete advanced simulation package.

With Tree C, flexibility is baked in from the start. For us, it’s important that our simulators can evolve with our clients’ needs. We don’t just hand over a standalone software product designed for a single purpose. Our approach is to provide a simulator framework which can add value right across your company – from development to training and operation.

Our proven technology gives heavy equipment, offshore, and remote handling operations a complete solution for modelling any complex engineering project. At the same time, users can perform tests based on real world data and conditions. And with real-time rendering to create the look and feel of real life performance, training operators can use it to learn how to avoid costly operational errors.

Looking for advanced and interactive 3D simulation technology for a highly-precise or high-risk engineering project? Tree C can help.