How To Achieve Maximum Yield With Simulator Training For Dredging

Although dredging can seem relatively straightforward, in reality, dredging projects can become increasingly complex and demanding, requiring expert knowledge. For that reason, it pays to ensure operators are properly trained.

For new or inexperienced dredger operators, there’s a lot to learn. Besides operating the machines, they also need in-depth knowledge of the conditions and environment. This includes things like different soil types, tides and currents, waves and water depth, obstacles and navigation – as well as the limitations of the equipment itself.

For example, how do they optimize the pumping system, and how do the pumps react, when cavitation occurs, and gas forms in the mixture causing an efficiency drop? The operator needs to know how to solve – or better still – avoid issues like this occurring. That’s where a dredging simulator can help. But how can it enable dredging operators to achieve maximum yield?

Improved Operator Training

There are three main options for learning how to correctly operate dredging equipment: a real-world operation, a standard off-the-shelf training simulator, or a fully-immersive and interactive dredging simulation.

Training on real-world equipment, of course, offers the most realistic experience, but if something goes wrong, there could be costly damage to equipment. Take the previous example of cavitation. When this occurs, the gas bubbles can collapse and damage the blades inside the pump. If no action is taken, then the equipment will be damaged and may need to be replaced, creating a costly interruption to production.

Not only that, but training interferes with real-world projects. That’s because – for good reason – training operators takes time and therefore slows down operations and limits equipment availability for actual production.

The alternative is to use a process simulator. Standard training simulators can be useful for learning about generic operating parameters. At the same time, the ‘closed’ simulators that typically accompany new equipment are great for learning how to operate a single piece of machinery in isolation. However, to prepare future operators for dealing with specific operational circumstances and to make sure they become fluent in operating a range of equipment, a more flexible and tailored approach is the answer.

That’s when a dredging simulator can give operators real situational awareness. It does this by providing a fully immersive and interactive experience of operating equipment in the context of a specific environment or operation. Built on top of a generic technology platform, Tree C promotes a flexible and efficient ‘Framework’ method for dredging simulation that requires a range of bespoke equipment and operational scenarios. The combination of standard building blocks and custom content, like proprietary production ratios, results in a fast and efficient way of creating a tailor-made training experience. This can then be targeted at operating an actual dredging fleet with maximum production rate.

An Evergreen Solution

Unlike standard training software with a fixed shelf-life, a more custom and flexible approach can evolve with your entire dredging fleet and its machinery. The data from multiple ships carrying different types of equipment can be realistically re-created inside the simulator. Not only that, but it can also be simulated in a realistic 3D digital model of any digitally-mapped environment.

Simulation hardware can be as simple or advanced as it needs to be. For example, technical teams can plug in actual hardware to replicate the real-world experience. On top of that, actual control systems are incorporated into the simulation – so when there’s an update ready for the real world, the simulation can also be updated.

What this also means is that a control system update can be safely tested in a virtual environment before it goes live in the real world. Once you have a dredging simulator in place, you have an evergreen solution, not only for all your training needs, but also for engineering validations, for automation purpose, and mission preparation. So there’s no need to replace an entire simulator when equipment or related software gets an upgrade.

In addition, we’ve recently developed a set of training building blocks that can be configured and re-used in many ways. This enables our clients to shape training to their exact needs without requiring Tree C to make changes and provide new versions.

Simulate An Entire Dredging Fleet

The framework approach allows the creation of a complete and expandable ‘asset library’. Every vessel and every piece of machinery in your fleet can be faithfully represented within one virtual environment. Gone are the days of running multiple simulators to represent different assets. With the right data, you can now put every vessel into a realistic 3D representation of an actual environment – both above and below the waterline – including an up-to-date seabed shape.

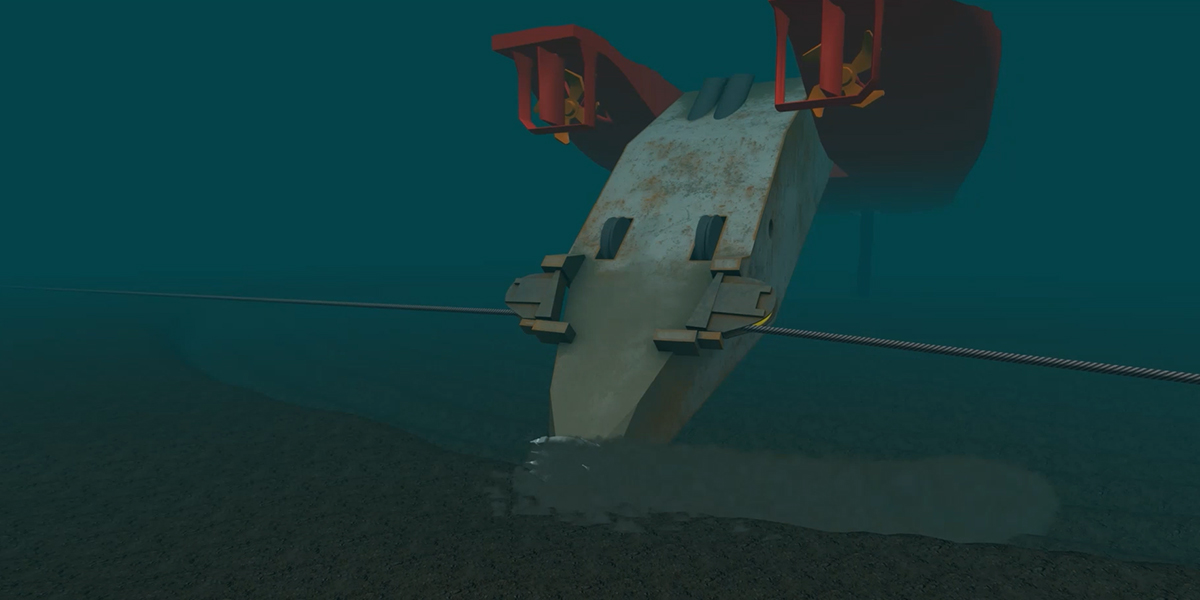

As well as creating an accurate visual representation of a 3D environment, the simulator can also replicate real-world soil types. With our dynamic soil model, it’s possible to simulate the interaction of different types of dredging equipment with the seabed. That means dredging companies can predict the impact of a particular dredging operation. At the same time, the virtual environment can be continually updated with real-world data to maintain an accurate representation of a subsea environment as it changes during production.

Another advantage of the framework approach is scalability in hardware configuration, ranging from laptop to a full multiscreen setup, resulting in an immersive dredging simulator, not only for training individual operators, but entire teams as well. Rather than their first collaborative effort taking place onboard an actual vessel in a live operation, teams can role-play real-world scenarios in a safe and lifelike virtual environment. In fact, it’s possible to recreate an entire ship’s bridge using projectors, multiple screens, and connectable hardware.

Future Proof Applications

Through an ongoing collaboration with Tree C, dredging companies can maintain a digital twin of their entire dredging fleet that can evolve with its real-world counterparts. Using real-world survey data, they can build an expanding library of virtual subsea environments which can be continuously updated with the most recent project data.

The advantages of a Tree C dredging simulator framework over standard or generic training software are clear: improved training resources for both individual operators and entire crews; virtual equipment and subsea environments which evolve with their real-world counterparts; and the option to represent an entire fleet in a single simulation. A valuable digital asset contributing to increased safety, efficient engineering, and maximized production for dredging companies.

Find out more about 3D simulation solutions from Tree C.