How SMD uses Tree C simulators to enhance ROV training and engineering

Soil Machine Dynamics (SMD) invents and engineers solutions for some of the world’s toughest underwater challenges in both industry and the scientific community. The company initially began by engineering cable pipelines and cable protection systems for corporate giants such BT and BP. Today, SMD is best known for its robotic trenching systems and, more recently, its subsea remotely operated vehicles (ROVs).

SMD designs and manufactures subsea ROVs for a diverse range of sectors, from the construction and maintenance of underwater structures – such as oil platforms – to bespoke exploration vehicles for oceanographers. However, the correct and safe operation of this expensive and complex machinery requires extensive training.

Cost-effective and realistic training for ROV operators

—————————————————————————————————————————

“Wherever they’re located in the world, ROV operators – and the vessel’s crew – need to be highly trained. That’s because when working offshore, safety is paramount and time is money. ”

- Mark Collins, Business Development Director, SMD

—————————————————————————————————————————

Over the course of a year – factoring in things like insurance, food, travel, and so on – the cost of sending one person offshore to take part in ocean operations can run into millions. For that reason, these companies – SMD’s clients – need to avoid the cost of training operators offshore. They also need to keep trainees away from real subsea structures to avoid accidental damage and delay to live operations. The question is how?

One option is to use highly-sophisticated simulation techniques to not only bring the equipment to life virtually, but the environment as well – including real-world physics and subsea conditions. This technology – designed and built by Tree C – is not dissimilar to the technology inside video game simulations.

As an OEM, SMD engineers and builds the ROVs, and then uses simulators to train their client’s trainer so that they can train operators. This covers two related areas: how to operate the simulator, and how to use the equipment itself. In addition, the simulated environment is often used to train pilots for specific missions. With fully immersive simulations, entire control rooms can be recreated so that operators know exactly where to locate certain buttons and get familiar with using certain touchscreens.

What’s most important for training purposes is the accuracy of the interactions – how closely they mirror the real world look and feel. Thankfully, alongside realistic subsea structures, it’s also possible to connect physical controls to the simulators so that operators get as close as possible to the real-world operational experience. Whilst it’s possible to run a simulation using a mouse and keyboard, it doesn’t give the same quality of experience.

Re-create constantly changing real-world environments

—————————————————————————————————————————

“We quickly identified that Tree C had a great product. What attracted us to Tree C was the ability to customize both the vehicles, the subsea conditions, and the missions.”

- Mark Collins, Business Development Director, SMD

—————————————————————————————————————————

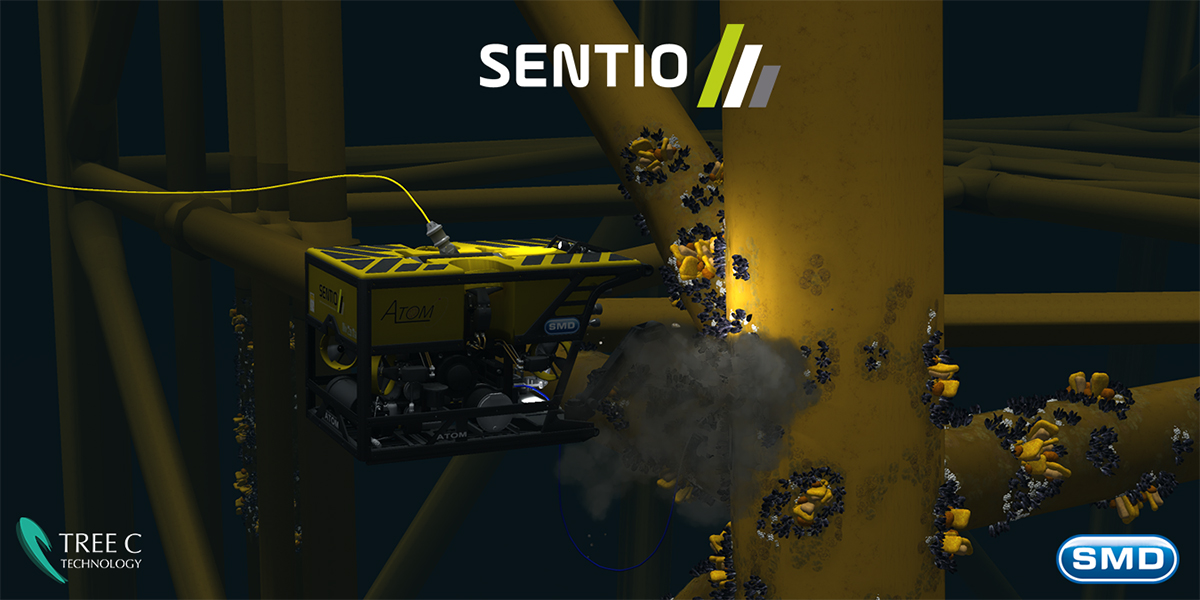

SMD’s fleet of vehicles lives virtually inside its own simulation platform – SENTIO – which is underpinned by Tree C technology. This library of 3D models holds digital twins of their real-world counterparts. They’re accompanied by a suite of tools and environments, which are ready and waiting to be connected to the replica control console at SMD. This is then used to provide training packages to companies.

A simulator is essential for training under realistic yet virtual conditions. It also mitigates costly damage to real equipment. For offshore companies needing to train their operators, they can buy in a bespoke simulator package, which can then be evolved over time in line with changes to their equipment or missions.

As already mentioned, this type of training is about more than just the equipment itself. Operators need experience with real-world conditions. As do the research and development (R&D) engineers at SMD itself. In fact, they use the same simulator technology to test out prototypes and modifications to see how they behave in different environmental conditions.

Like many other industries, ROV manufacturers are looking at ways to automate certain aspects of ROV operation. By attaching actual control software and hardware to simulated ROV equipment, it’s possible to measure its performance and test out automations in a safe environment.

De-risk complex offshore operations

Safety is a key driver for using ROV simulation in offshore operations. Take something like decommissioning. Typically, a smaller robot will be dispatched to map a 3D point cloud of the subsea structures. This can be compared with existing plans to identify changes and so on. This detailed dataset can then inform real-world operations.

With the planning in place, an obvious next step – sometimes missed out by offshore companies – is to test out the proposed operation using a simulator. The point cloud gets uploaded into the simulator alongside digital twins of real-world equipment – including machinery such as cranes – ready for testing. This means operators can identify potential issues before they arise and practise potential manoeuvres to see if they’ll work in the real world.

There’s no question that a fast and economical modelling of custom scenarios based on an existing platform can save both time and money. Especially when you consider that a typical operation can cost thousands per day. If something preventable does go wrong, it can take days to rectify, and the costs soon start to mount up.

—————————————————————————————————————————

“For Tree C it’s great to work with an innovative company like SMD. They have embraced the multipurpose aspect of our technology, using SENTIO for engineering and training. Moreover, SMD offers their clients bespoke simulation scenarios within SENTIO, to assist them in preparing and de-risking their specific missions.”

– Thomas Weder – Director of Business Development, Tree C

—————————————————————————————————————————

The future impact of ROV simulation

Forward-thinking companies working in offshore industries are already looking at ways to cut costs by reducing the number of people required onboard a vessel. Autonomous vessels and even autonomous underwater vehicles (AUVs) are currently in the research and development phase.

As well as legislation, water itself is a major barrier to the development of AUVs. That’s because communication speed is limited. Water absorbs RF signals, and lasers can currently only penetrate up to 20 meters. Sound is another option, but it’s very slow. That’s a problem because latency can lead to damaged equipment, with operators unable to make a manoeuvre in time.

The question going forward is: what if subsea robots become intelligent? Imagine if they could make smart decisions around things like collision avoidance. We’re looking at a future where simulations are used as a real-time monitoring tool and as a safe test environment for autonomous control systems.

Clearly, there is huge potential for ROV simulation in the offshore industries, and this is just the beginning in terms of potential use cases.

Find out more about using Tree C technology to enhance ROV training and engineering. Talk to a specialist at Tree C. Get in touch