How Graphitech Is Using VR4Robots In Nuclear Reactor Decommissioning

Today – and for years to come – the world faces the challenge of dismantling graphite nuclear reactors. Next to the Chinon nuclear site in France, engineering company Graphitech is starting a test program to evaluate safe and effective technological solutions for decommissioning.

As part of their work, Tree C’s VR4Robots simulation technology is being used to support the design and qualification of cutting-edge remote operation machinery.

Automating the extraction process

—————————————————————————————

“Using virtual reality technology to reproduce an environment makes it possible to anticipate many of the risks that will be encountered during the project execution phase.”

– Denis Depauw, Simulation Technical Lead, Graphitech

—————————————————————————————

Graphitech – a joint venture by EDF and Veolia – unites EDF’s expertise in dismantling engineering in the nuclear industry with Veolia’s deep knowledge of remote handling for nuclear environments. Its goal is to design and develop the required technologies, including articulated robotics arms and dismantling tools, to safely extract graphite bricks and piles from reactors.

Graphite was commonly used in this type of nuclear reactor to regulate and sustain the reaction process. The decommissioning of this type of reactor is now happening for the first time. At Chinon, the fuel has already been removed and handled separately. One of the key tasks remaining is the safe extraction and storage of seven layers of graphite bricks – about 28,000 of them – which must be safely extracted and stored.

Robotics offers a solution for the safe removal of these bricks. Although time is not the mitigating factor, traditional robotics – with a human in the loop – could take months or even years to complete the extraction. For that reason, Graphitech has been conducting a feasibility study that looks at automating the extraction process, opening up the potential for round-the-clock operations.

The problem is that prototyping multiple variants of large robotic arms for this purpose is prohibitively expensive. That’s why Graphitech turned to Tree C and VNS to support the design and qualification of this vital technology with VR4Robots simulation software.

Validating design and engineering

—————————————————————————————

“VR4Robots has proven to be an indispensable tool for testing and operating our robotic engineering work for Mitsubishi Heavy Industries, related to the investigation and decommissioning of the damaged reactor at Fukushima, Japan. Using this technology now for Graphitech, provides an efficient and reliable digital mockup to tackle the specific engineering challenges of this remote handling project at an early stage.”

– Simon Delavalle, CTO, Veolia Nuclear Solutions UK

—————————————————————————————

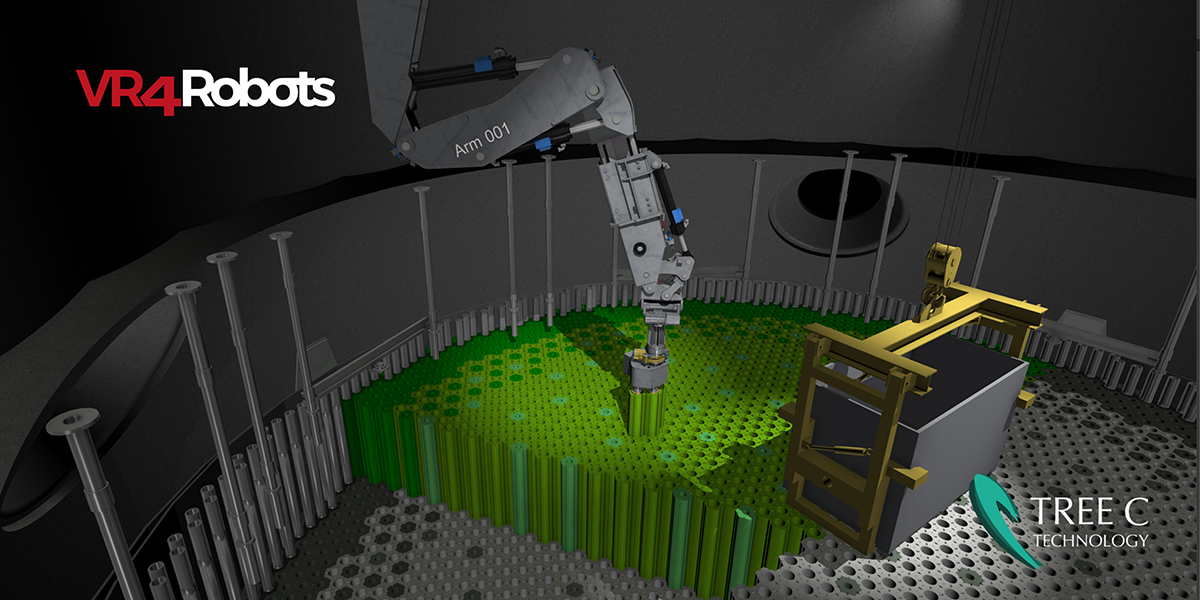

Tree C developed a simulator of the Chinon reactor, Graphitech’s robot, and its accompanying deployment and graphite-block retrieval systems, which were designed for dismantling the reactor by first removing the graphite blocks.

After the initial delivery of a prototype simulation to demonstrate Tree C’s capabilities, development quickly advanced to a fully functional simulator. This contained the latest states of designed equipment together with a floor filled with interactive graphite blocks.

With limited visibility in a hazardous environment, it’s important that the movement of equipment is limited and controlled. With real-world physics simulation in play, this virtual environment facilitates reliable validation of the removal procedure with the designed robotic equipment.

The simulation quickly revealed that the study model of the basket crane (intended to carry the bricks) had too much movement and needed to be further refined. At the same time, it enabled engineers to test out the positioning of the basket in order to make it accessible by the robotic arms.

The monitoring view inside Tree C’s simulator also provided accurate insights into the effect of forces on the robotic arm itself. Comparing the simulator’s data with manual calculations revealed a high level of accuracy – giving Graphitech confidence in the validations of their robotic structure designs.

The impact of VR4Robots

—————————————————————————————

“VR4Robots was developed to support nuclear remote handling projects with reliable digital mockups and has developed into a complete and versatile toolkit. It’s rewarding to deliver this technology to such an important and pioneering project and work with the Graphitech and VNS remote handling specialists to further tailor the simulator to their specific needs.”

– Sander Tolsma, Technical Manager, Tree C

—————————————————————————————

Graphitech has all the right expertise to design an autonomous or semi-autonomous robot that can extract and safely remove graphite bricks from Chinon and other graphite-moderated decommissioned reactors. What it needed was a cost-effective way to reliably test and validate its designs.

After some early-stage training and support from Tree C and VNS, the Graphitech engineering team now understands how to operate the simulator and the workflow needed for content creation. They also have the proficiency to add or adjust the simulated content internally. This gives them the means to cost-effectively iterate on their designs.

Going forward, Graphitech can lean on Tree C to support them with more technical aspects of their simulator, but by and large they’re up and running independently. By starting early with simulation technology, Graphitech is able to cut the costs associated with developing multiple physical prototypes.

That’s because potential issues can be alleviated before the machinery goes into production through rigorous and safe testing in a virtual environment. Let’s say one of the pistons needs to be larger or a second one is required to support the load, those adjustments can be made within the simulator first – saving thousands of Euros.

Designing and rigorously testing robotic machinery in a simulated environment means that when the equipment finally goes into production, Graphitech can be confident that it will safely fulfill its purpose. Not only that, but the robotic arms and tools developed for Chinon can also be implemented in other graphite-moderated reactors around the world.

Find out more about using VR4Robots to design, engineer, and test robotic equipment. Talk to a specialist at Tree C. Get in touch