De-risking Deep Sea Mining Using A Virtual Reality Monitoring System

The seafloor is a treasure trove of metals, minerals, and rare earth materials. So it’s no wonder that the deep sea mining industry is gaining increasing interest – particularly from countries looking to reduce their dependence on the mining exports of a single nation.

The trouble is that subsea mining operations are exceptionally challenging. Low visibility in a hazardous environment leaves no room for error. One mistake can cause damage to highly expensive equipment or even negatively impact the environment. What’s needed for a safe and successful operation is efficient execution and minimal downtime.

That’s why – from equipment design to deep sea operations – de-risking through simulation and monitoring is essential. It’s also where a VR subsea monitoring system can add real value to operations.

What Is A VR Subsea Monitoring System?

A VR subsea monitoring system is a multipurpose framework combining 3D visualization technology with a wide range of simulation and mission planning tools. The system is designed to support subsea operations with a clear real-time view of the work site. It can also be used as a sophisticated planning and monitoring tool, incorporating VR and AR (Augmented Reality) functionality.

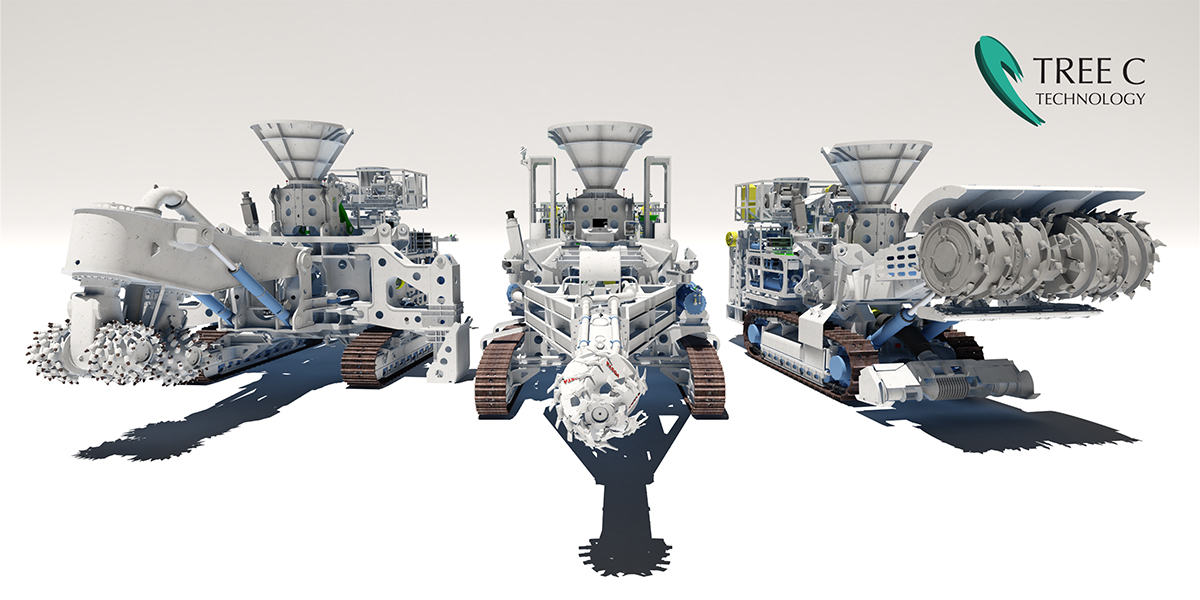

Tree C first developed a VR monitoring system for the deep sea mining operation by Nautilus Minerals, which was eventually put on pause. By the time the project ended, the VR monitoring system was largely complete. Since then, the technology has been iteratively improved. It’s now ready to support new initiatives in the quest for rare materials beneath the seafloor.

How VR Monitoring Supports Deep Sea Mining

VR monitoring systems support deep sea mining in two important ways: de-risking operations and increasing operational efficiency. By harnessing all the available data – from 3D models of subsea assets to 3D maps of real underwater environments – VR monitoring offers reliable virtual representations of live operations.

Visualizing the seafloor via scan data – and updating it in real-time – VR monitoring realistically simulates things like soil interaction, production rates, and models potential impact on the environment. VR monitoring also presents operators with a clear view of the machines at work and the attached hoses, umbilicals, and other seabed assets – something that’s not possible by using cameras in low visibility conditions.

With improved visibility, offshore teams have a better view of their operations, which helps to reduce the risk of damaging expensive subsea assets and sensitive cables. Besides live monitoring, using the technology in planning mode, allows companies to plan, rehearse and optimize operations in advance. The end result is a multipurpose operational support system that is scalable and allows any number of operators to use the system simultaneously, for monitoring, planning and training

What’s Possible With VR Monitoring Systems

Tree C’s virtual view of the work site is vital for successful operation, whilst the planning tools enable operators to execute their challenging missions with confidence. Here’s a list of what’s possible with our 3D visualization and VR subsea monitoring systems:

Monitoring

- Real-time visualization of the worksite: The operator navigates through an accurate 3D representation of the work site, including all stationary and moving machines, creating views from any perspective.

- An enhanced view of low visibility environments: Depth and turbidity from asset actions make subsea camera views too inaccurate for monitoring. 3D visualization provides a crystal clear view, with accurate positions and movements.

- Create multiple, smart views of the operation: Smart views can be configured with schematic color usage to indicate terrain steepness, cutting depth, target depth or soil type. With cross-sectional views, operators can monitor the work site and equipment in action from any plane and angle.

- Simulated cable physics: Flexible hoses, lift wires and umbilical cables are simulated with high accuracy. Their shape is continuously monitored, as is their proximity to hazardous objects. With limited sensor data available, this physics based prediction of cable shapes is an important aid in preventing collisions.

- Customized alarm systems: Hazardous areas can be marked by the operators. Through AR, dedicated warnings are triggered to prevent the equipment from entering ‘keep-out’ areas.

- Real-time terrain update: The virtual seabed is modified in real-time, both as a result of the actions of the simulated equipment on the terrain and as a result of actual sonar scan data. This provides real-time feedback on the production.

Planning

- Path planning: With the path planning tool, a track to relocate assets can be prepared, edited, and tested. This track can be distributed to any operator station in the system.

- Area marking: In preparation for a mission, areas in the virtual terrain model can be marked, as a target area or as a keep out-area. Alarm triggers can also be added that will activate a warning when approaching those areas.

- Practice runs: The system can switch to simulation mode to practice moves and cutting actions before returning to the live monitored work site.

- Feasibility studies, safety, and analysis: Different approaches can be tested and compared in the virtual environment, giving valuable insights on methods, efficiency, and risks in a realistic setting before the actual job is started.

- Debriefing: All actions can be recorded for later playback during debriefing, contributing to the efficiency and safety of ongoing and future operations.

Based on a powerful combination of Tree C’s generic technology building blocks and client-specific content and configurations, our engineers deliver systems that are fully tailored to support your subsea challenges. Talk to a specialist at Tree C.