3 Signs Your Engineering Projects Needs Advanced 3D Simulation Technology

From subsea monitoring to robotic worksite visualization, it can be a real challenge to find cost-effective solutions for de-risking complex engineering projects. On top of that, expensive equipment requires rigorous testing and comprehensive user training to mitigate the risk of costly errors.

That’s where advanced 3D simulation technology comes in. It can help you visualize inaccessible environments and safely test equipment and control systems using the most realistic and advanced physics simulations. But how do you know when the time is right to invest?

In this blog post, we explore 3 signs that your high-level engineering project is in need of next-level 3D simulation technology: the need for well-trained operators, the need for a safe test bed for complex engineering, and the need to deal with harsh or low visibility operational conditions.

1. Training Operators

Comprehensive training is essential to ensure the smooth running of heavy equipment, particularly in potentially dangerous environments.

The difficulty with training of this sort is that it needs real-world data, conditions, and physics to make it relevant and fulfil its purpose. Sure, you can guide operators through a training manual, and teach them the relevant theory, but in the end, what they need is practical experience of using the expensive equipment.

With an advanced training simulator, you get a fully functional digital twin of the real equipment. Not only that, the virtual equipment is connected to the actual controls and hardware. Realistic visuals and programmable scenarios, give the training the look and feel of the actual environment without exposing real equipment and people to danger.

2. Engineering Support

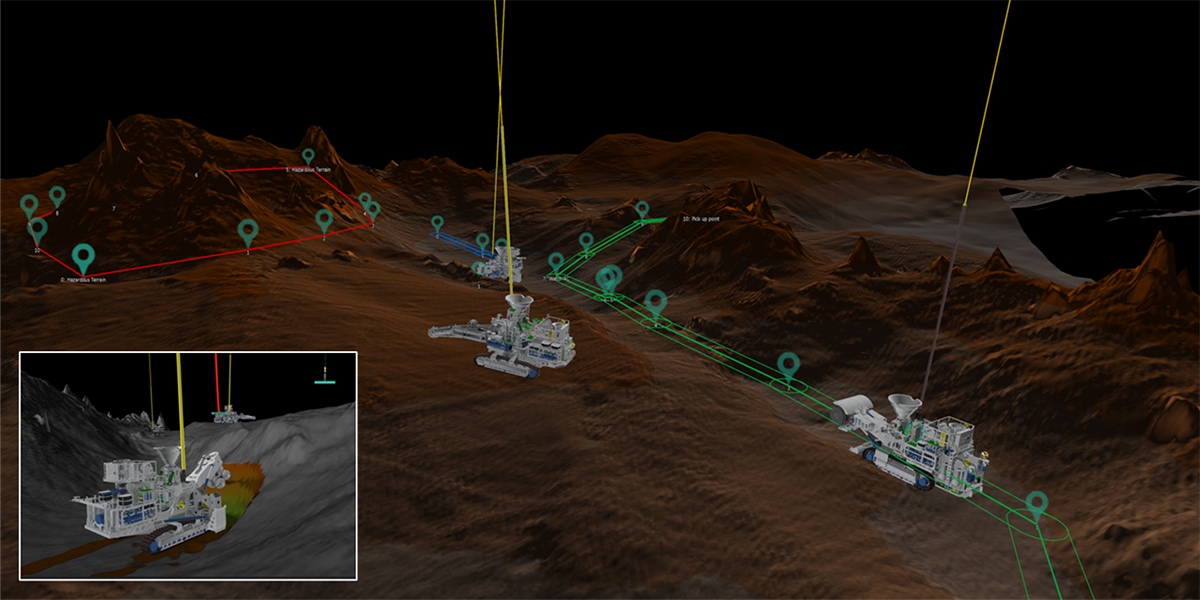

With a complex engineering project, such as deep sea mining or nuclear decommissioning, it’s essential to thoroughly test electrical and mechanical equipment before going into production.

Incorporating simulation early on in the design process helps to de-risk the project from the get-go. Testing can take place within a safe and realistic setting, exposing risks and mitigating costly remedial action further down the line.

The other advantage is that VR testing helps to ensure ongoing maintainability. For example, it can validate the accessibility of key components and, at a later stage, enable engineers to test the viability of changes to the control system before going live.

3. Seeing Dangers

When you have ongoing operations in a hazardous environment, safety is paramount. This is especially true for remote handling and the use of robotics, when environmental conditions dramatically impact visibility and accessibility.

The beauty of an advanced 3D simulation, which uses actual real-world data, is that it gives you a clear view in environments where there is restricted visibility. When camera images are impaired by damage, high radiation levels, or turbulent conditions, it’s still possible to render accurate VR representations using sensors and other inputs.

3D simulation can give you clear operational monitoring in dangerous and unpredictable conditions. And by repeatedly scanning the physical environment, it’s possible to reconstruct an ever-more precise model to guide the remote operation.

Reading The Signs

It’s fair to say that there’s rarely a single eureka moment when companies realize they need advanced 3D simulation technology. There are usually a number of contributing factors which lead them to the conclusion that they need a sophisticated software solution for de-risking their engineering project.

That said, our experience shows that when equipment is not available for training, or the use of real equipment carries an inherent risk, 3D simulation can provide a robust and reliable alternative training environment.

At the same time, testing out new equipment in a virtual environment– say a robot for remote handling – can help validate things like performance, functionality, and accessibility both before production begins and during its lifecycle.

Moreover, the benefits of generating a live clear 3D visual to monitor an ongoing operation are obvious, adding safety and efficiency to operations under challenging conditions.

More and more companies are realizing that when it comes to complex engineering, the use of 3D simulation technology adds value for operator training, engineering support and monitoring.

Discover the capabilities of advanced simulation technology. Talk to Tree C.