Our solutions

Tree C embraces technological challenges and is always looking to add value based on the combined expertise in simulation technology and engineering. In a flexible cooperation with our clients, we configure the optimal workflow together.

Training simulators

Tree C’s training simulators provide a fully functional digital copy of the real equipment. The benefits are obvious, training can take place in a safe, but realistic setting and the actual, expensive equipment does not need to be available for training time.

Tree C offers the trainee an immersive experience. The virtual equipment is connected to the actual controls and control hardware and the realistic visuals can be configured in any projection setup. Specific training functionalities make training on the simulator extra valuable. The instructor can monitor the task from any viewing point and can introduce situations or calamities the trainee needs to respond to. Pause and resume functionality allow the instructor to provide feedback during the training and automated feedback from the system also increases the effect of training.

- Compact laptop version up to full console immersive hardware in the loop simulator

- Realistic virtual environments with physics-based equipment interaction

- Connect to control systems and real control equipment

- Instructor station for composing, monitoring and interaction

- Pause, save and resume to restart training from any point in the process

- Configurable training scenarios, also tailor-made

- Automated warnings and feedback

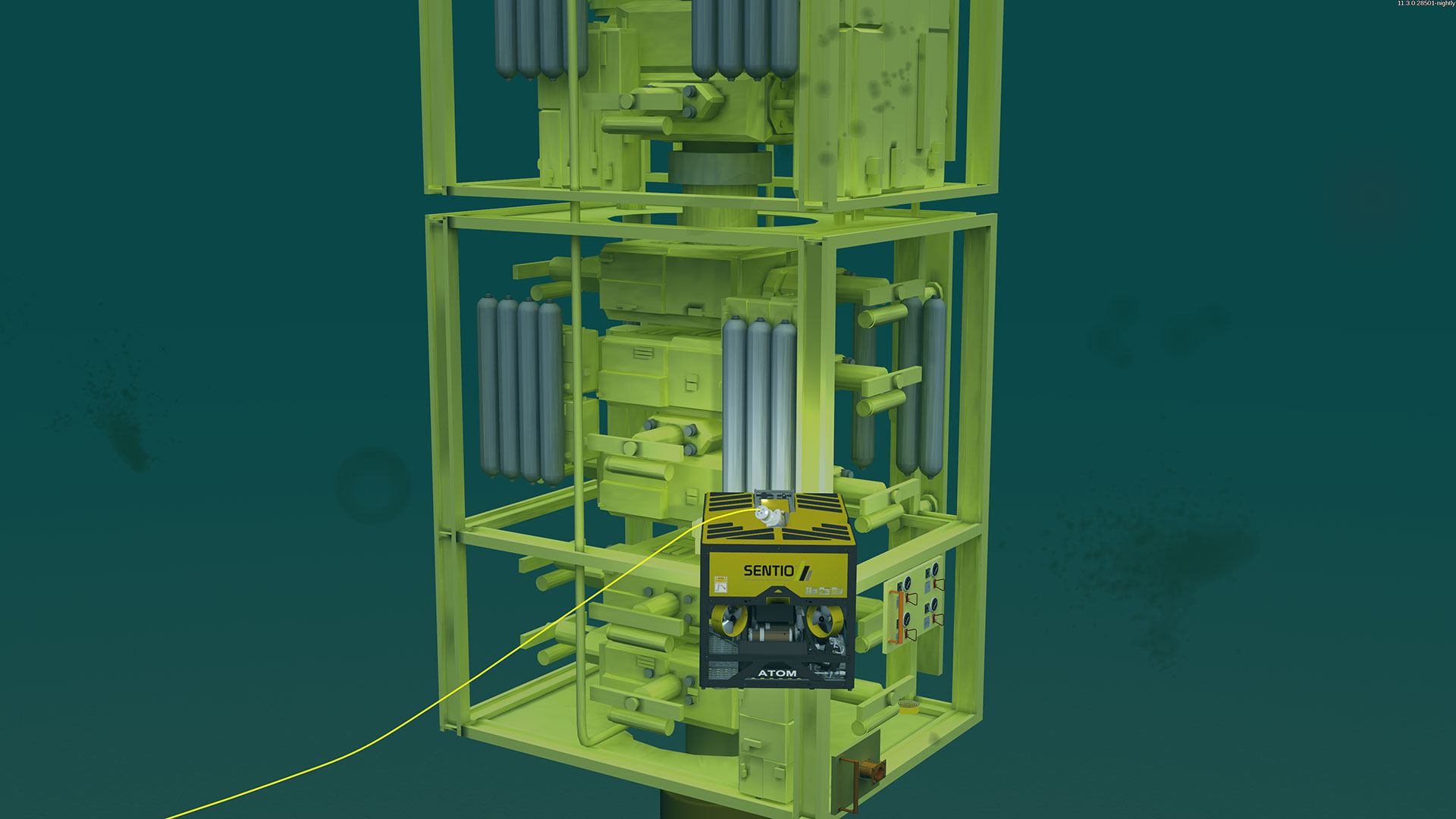

Subsea monitoring

The typical subsea challenge is to work with low visibility in an often hazardous environment, with the risk of damaging expensive subsea assets and sensitive cables. Efficient execution of the operation and minimizing downtime are essential for a safe and successful subsea operation.

Tree C’s subsea monitoring system is a multipurpose framework combining 3D visualization technology with a wide range of simulation and mission planning tools. The system is designed to support subsea operations with a clear real time view on the work site and is a helpful planning and monitoring tool, making use of the endless possibilities of VR and AR.

Based on a powerful combination of Tree C’s generic technology building blocks and client specific content and configurations, our engineers deliver systems that are fully tailored to support your subsea challenges.

- Real time asset tracking

- Soil and production monitoring

- Visualization of sensor data

- Multiple visualization options

- Automated warnings

- Umbilical simulation

- Planning mode

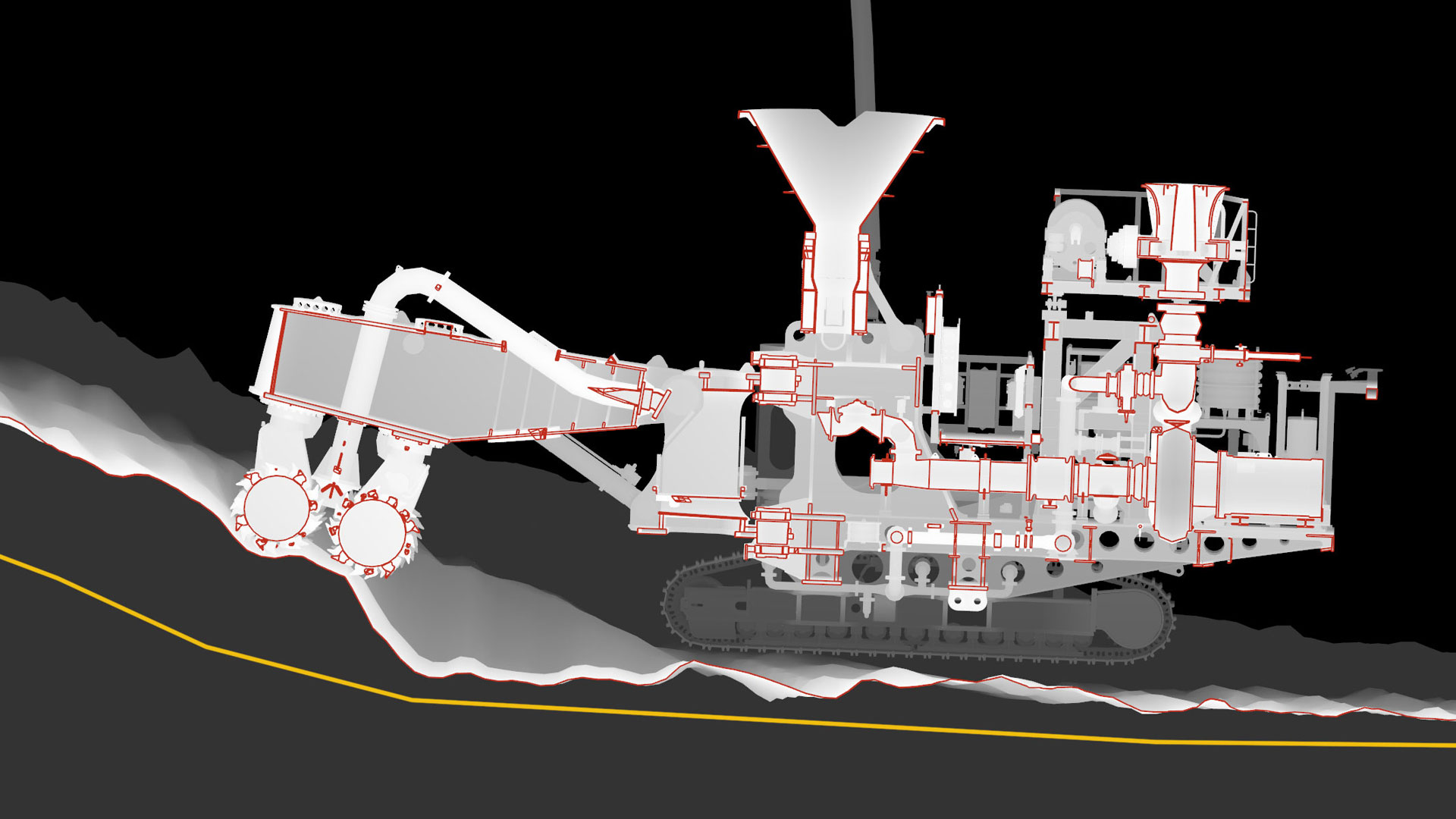

Engineering validation

Tree C promotes to start applying simulation early in the design process. A virtual test environment has proven extremely valuable in many cases. With advanced physics simulation the equipment engineering, both mechanical and electrical, can be tested in a realistic setting before starting the actual production. Also maintainability can be ensured, by testing in VR whether all components can be reached and/or removed for maintenance. In a later stage control system updates can be validated in the simulator before being released on the actual equipment.

- Evaluating designs from any point of view

- Virtual mockup studies

- Advanced physics simulation

- Accessibility studies

- Control system testing

- Design, showcase and project communication

- Support of FAT procedures

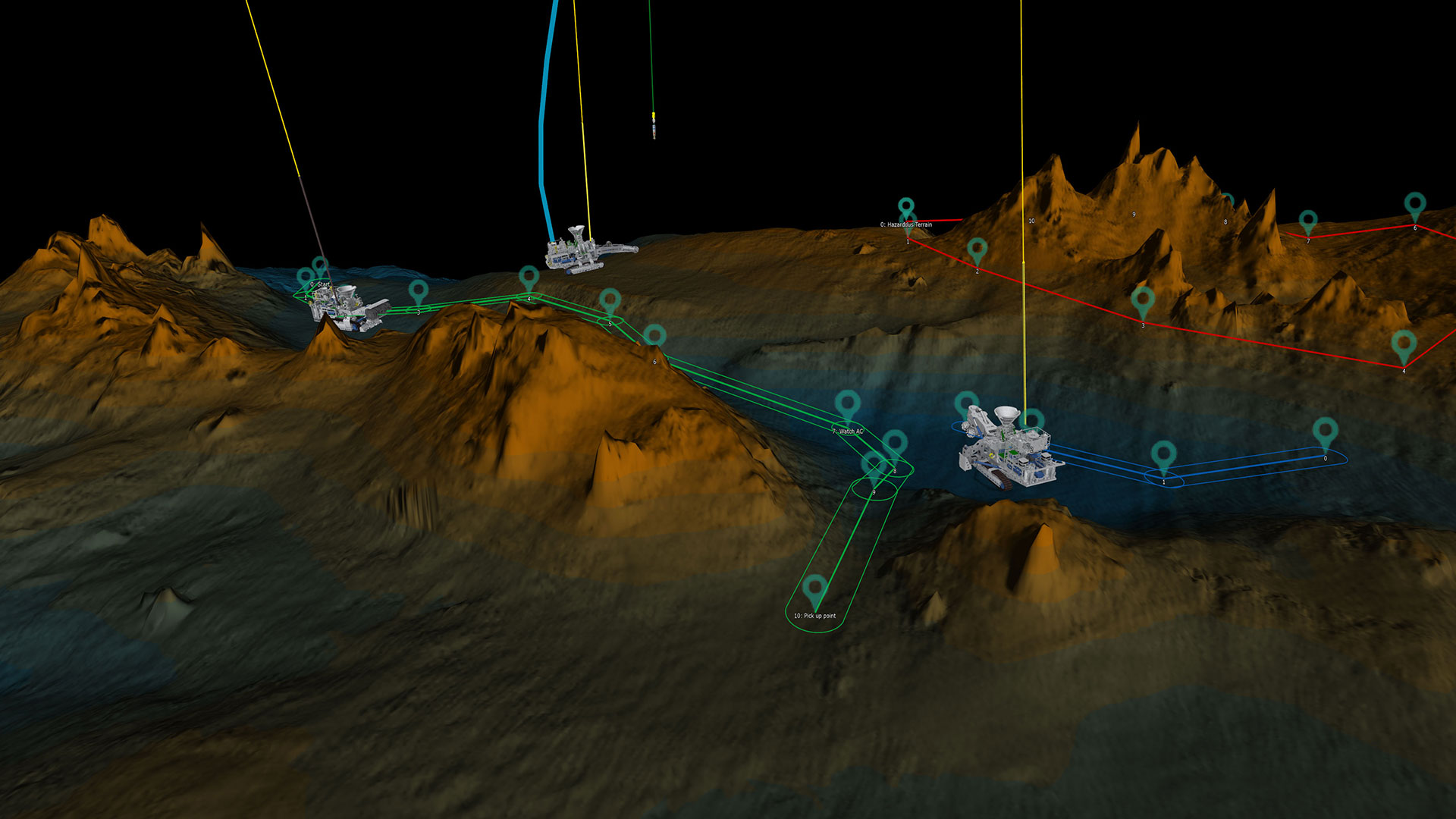

Mission planning

New scenarios and missions can be added to a simulator. This way a specific operation can be prepared and rehearsed in advance. A client specific library can be filled with relevant custom tools, structures or payloads, giving endless possibilities to configure any operation. Weather-critical operations can be rehearsed and timed under specific wind and sea state conditions.

- Rehearsal

- Alternative approach studies

- Feasibility studies

- Library with scenario components

- Timing of operation (define weather window)

- Communication of mission approach to operators and client

Work site visualization

Tree C offers various solutions for real time visualization of work sites. In cases where no reliable 3D environment models are available, for example when sites are inaccessible due to damage or high radiation, Tree C will reconstruct the environment based on a combination of various sensor and other available inputs. Also, when operation in subsea high turbidity conditions, Tree C generates a crystal clear view on the live operation.

- Reconstruction of environment

- 3D modeling

- Point cloud visualization and editing

- Fusion of point cloud and CAD data

- Laser and sonar input

- Photo and video projections in VR

- Markers, annotations, measurements in 3D

- Multipurpose soil model

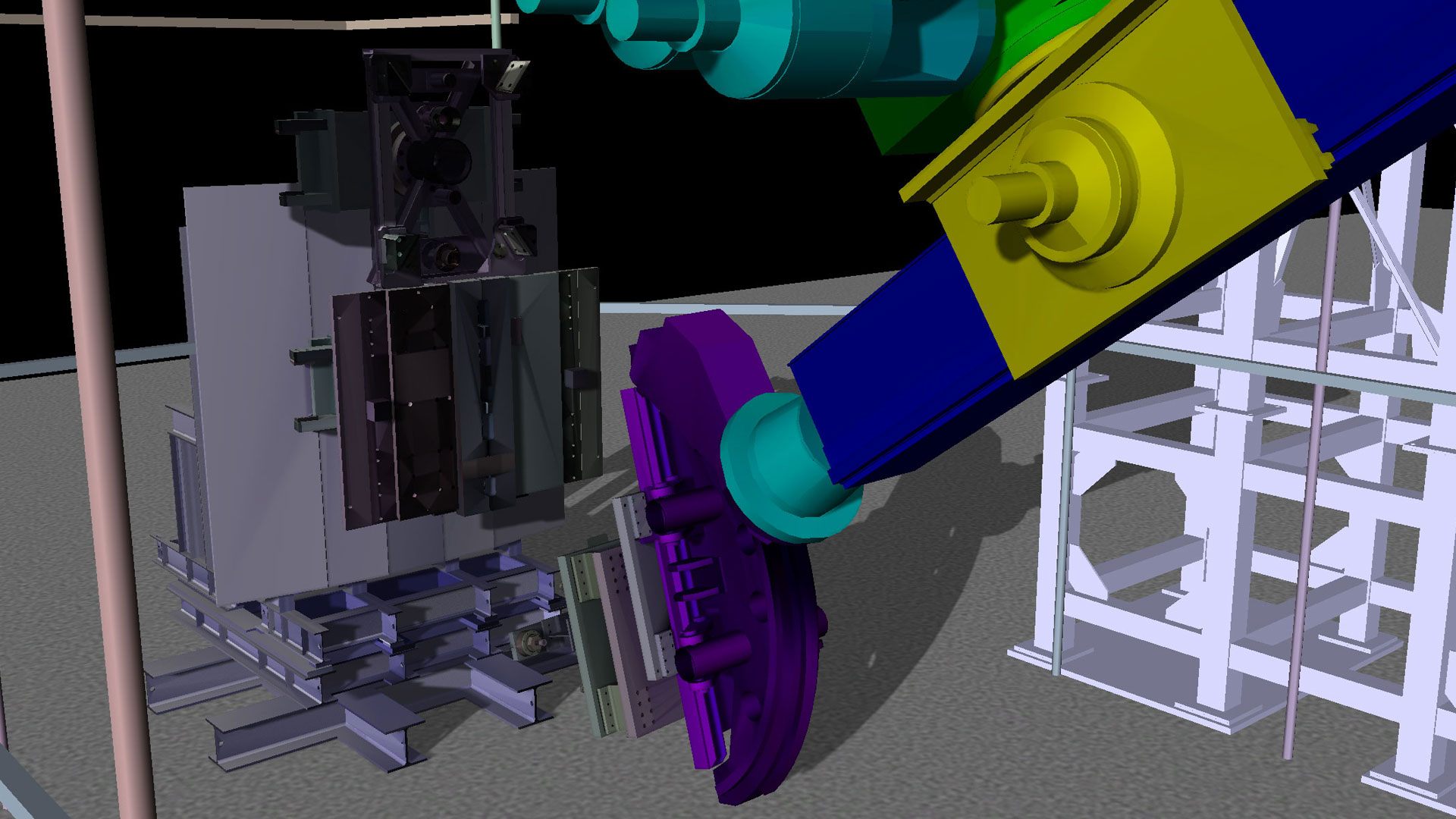

Remote handling

Tree C supports remote handling operations with kinematic and physics based robot simulation. The dedicated VR4Robots® software is an excellent tool to prepare and validate remote operations. Our real time interactive visualization technology delivers a smart visual on the complete remote handling process, both in preparation and during actual operation.

- Interactive visualization of designs early in the process

- Validation of remote maintainability of equipment

- Kinematic and physics based robot simulation

- Digital mockup functionality

- Reach studies and feasibility checks

- Real time deflection calculation and collision detection

- Simulation and monitoring of live operation

- Multi operator RH control room configurations